Landscape Architects designing outdoor spaces for freezing climates have specific challenges to consider when they’re selecting building materials. Dealing with freeze-thaw cycles and de-icing agents can cause a few (potentially costly) headaches, so it helps to be strategic when designing these types of projects.

Taking precautions and choosing the right products will protect your outdoor design, even when snow and ice threaten the durability of that space.

The Damage That Winter Weather Brings

There are a few ways that a harsh winter storm can damage your commercial property’s exterior design.

While regular maintenance helps to protect your hardscaping year-round, ice and snow can have a significant impact on even the most durable building materials. Here are a few things to look out for:

- Freeze-thaw cycles will degrade materials that aren’t manufactured for durability.

- If you’ve got clogged permeable paver systems, ice and snowmelt that doesn’t drain away can freeze and cause damage.

- De-icing agents can degrade hardscaping materials, especially when applied frequently throughout the winter season IF the products are not made to resist such damage.

- Scraping snow and ice off of surfaces can damage the materials used in your design.

There are a few solutions that architects can look to, however, to help preserve and protect the outdoor spaces they design.

Solutions to Help Your Exterior Design Survive the Cold

Dealing with ice and snow means you’ll need to create a safe and clear space for visitors to travel. There are a few things to remember when it comes to keeping that area user-friendly.

Use the Right De-Icing Agents

DO use sodium chloride (rock salt) on surfaces. DON’T use magnesium chloride or calcium magnesium acetate (CMA).

Studies have shown that “concrete exposed to sodium chloride experienced only minor, if any, adverse effects, while specimens exposed to calcium chloride, magnesium chloride, or calcium magnesium acetate (CMA) experienced significant deterioration, including scaling, cracking, mass loss, and compressive strength loss,” says David Smith for the Interlocking Concrete Pavement Institute.

Apply De-Icing Agents Sparingly

Excessive applications of de-icing agents can cause serious damage to surfaces and will degrade the materials you build with, especially if the material isn’t made to handle the agents being used. Architects can ensure the durability of an exterior space by selecting pavers that have a warranty that covers deterioration caused by de-icing salt.

Shoveling and Plowing Paved Surfaces

The ICPI recommends removing snow and ice first, before attacking the area with a de-icing agent. “Do not use de-icing chemicals in place of snow removal but reserve them for melting ice formed by freezing precipitation or freezing snowmelt,” according to the ICPI. “Once loosened, snow, ice and excess de-icing salts should be promptly removed by plow or shovel to avoid a build up in concentration of the de-icing chemical(s).”

You should also shovel away any slush mixed with de-icing compounds — this mixture can corrode any metal surfaces nearby and kill off landscaping and vegetation in the area, so it’s best removed before it seeps into the environment.

Beat the Freeze with Beet Juice

In one study by the ICPI, preparing the frozen surfaces with beet juice helped to clear the area more effectively. In fact, cities are using a beet brine mixture to clear roadways during winter storms. That’s because beet juice slows down the freezing rate on surfaces.

“As moisture on pavement starts to freeze, the juice mixture slows the freezing process and enables the liquid to remain slushy longer. This allows crews more time to clear highways before the liquid turns to ice. Also, because there is less freezing, crews do not have to apply brine as often,” writes Alice Mannett for the Ottawa Herald.

Choosing Materials That Can Weather Winter Storms

Using permeable pavers, as opposed to asphalt or traditional concrete pavers, has helped architects around the world create more durable and weather-resilient solutions in their exterior designs.

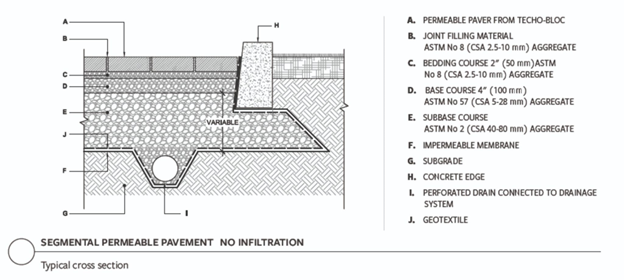

A hardscaping system that uses permeable pavers creates a passive filtration solution. It works by layering interlocking pavers on top of aggregate and a sub-base layer made of stone that collects the water, begins the filtration process and slows the water's reintroduction into the environment. This reduces runoff and won’t overwhelm stormwater systems.

This type of concrete paver system is “very durable and resistant to degradation because the high density of a paver limits de-icing material from entering,” reports David Smith with ICPI.

A permeable paver system offers a few other benefits when you’re dealing with freezing conditions, as freeze-thaw cycle can significantly degrade hardscaping materials over time:

- The concrete pavers won’t absorb or trap water because they’re permeable, which minimizes the risk of water freezing in the paver layer. “In addition, a high cement content helps a paver resist damage from the stress of expanding ice,” according to ICPI.

- A permeable paver design prevents water and snowmelt from pooling up on any walking surfaces and freezing (or refreezing) over time, creating a safer environment for area visitors. The precast nature of the pavers provides an easier (and safer) surface to walk on, unlike asphalt, which has a more heterogeneous surface that can be harder to travel on. This permeable system also minimizes the need for repeated de-icing applications when there are multiple freeze cycles.

- Permeable solutions help to reduce flooding events as the pavers allow water to travel through them more slowly and collect in the base layers. This prevents stormwater systems from icing ver and getting clogged.

More Benefits of Permeable Pavers

Permeable pavers are an attractive addition to your commercial building’s exterior, but they come with a few other benefits when you’re working in cold climates.

Using de-icing agents on an asphalt surface results in a high concentration of chloride in water runoff. “The chloride component of chloride-based de-icers does not easily precipitate, is not biodegradable, is not readily involved in the biological process, and does not adsorb significantly to mineral/soil surface,” according to the Minnesota Stormwater Manual. “As such, chloride is highly mobile and can impact the soil, vegetation, groundwater, surface water, and air.”

Permeable pavers, however, reduce the amount of chloride making its way into the surrounding environment. A recent study in Ontario showed a peak concentration of 20,000 mg/liter with asphalt runoff; permeable pavers peaked at 8,000 mg/liter, a 60% reduction.

Permeable pavers also mean that you don’t need heated pavement designs to reduce the amount of snow/ice build-up. If your client is insistent on having heated pavers however, you can pair permeable pavers with non-permeable heated pavers, especially for smaller, heavily-trafficked areas. The non-permeable products can be designed to drain onto the area designed with permeable pavers, to reduce flooding hazards for a safer entryway or sidewalk space.

Paving Solutions That Keep You Prepared

In climates that see frequent winter storms and freezing temperatures, it helps to choose building materials that you can depend on.

Techo-Bloc offers permeable pavement solutions that keep walkways clear and entrances safe for building visitors. And Techo-Bloc pavers also come with a warranty that covers the structural integrity of their products, including damage from sodium chloride de-icing agents.

Stand by your exterior design by building with materials that will stand up, even in the harshest winter climates. Want to learn more? Browse our collection of resources and guides here.